Do you know the 5 principles of lean manufacturing? They go as value, value stream, flow, pull, and perfection. The last principle, perfection, is nearly impossible to achieve, especially if the process has problems.

One of the biggest problems faced in manufacturing is inefficient task management, which leads to other issues, including the inability to meet deadlines and resource wastage. However, Kanban boards have made managing workflows easier and more efficient.

Wondering how you can make a Kanban board and stay organized? Here are five Kanban board examples for lean manufacturing and some best practices. Follow them and stay ahead of your deadlines!

In this article

What is a Kanban?

Translated to “visual sign” or “visual card”, the Toyota production team first designed the Kanban board in the 1940s to keep the work progress transparent and improve their manufacturing efficiency. A few decades later, David Anderson, in 2007, popularized Kanban boards to visualize work processes on a blank canvas.

Today, Kanban boards are widely used as a visual project management tool. These boards graphically illustrate work processes, track the tasks’ progress and maximize efficiency.

An average Kanban board has cards, columns, unit groups, and swimlines to allocate activities, their progress, and the work needed to complete them. Given their scalable and versatile structure, these boards are used across industries, from automotive production teams to pharmaceutical management and manufacturing inventories.

5 Examples of Kanban Boards in Lean Manufacturing

Let’s check out how to improve productivity and streamline tasks by integrating Kanban boards into manufacturing processes.

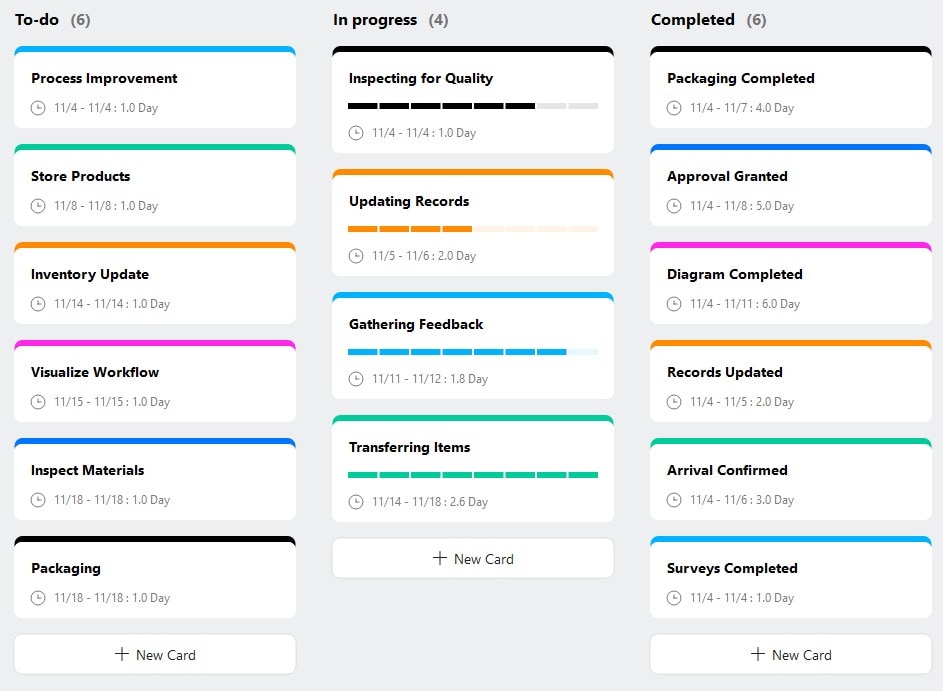

Task Management Kanban Board Example

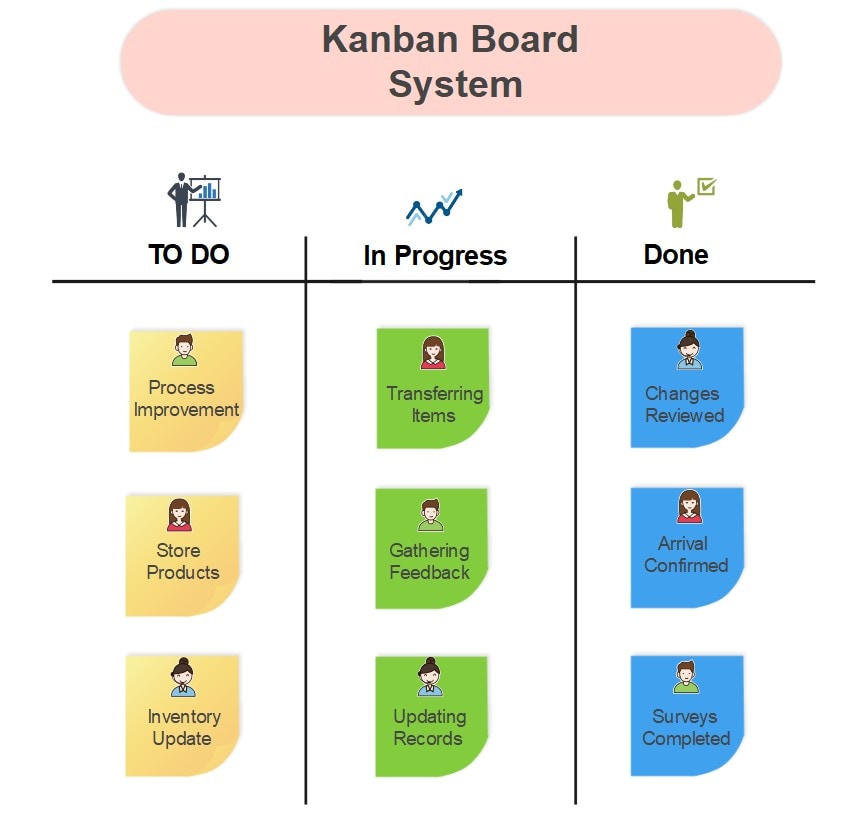

Here is the most popular Kanban board format tracing a simple yet effective task management schedule for a manufacturing team. It captures the entire workflow, from inspecting materials and packaging to arrivals and surveys.

The creator has organized processes into three groups: to-do, in-progress, and completed, making it understandable for other team members.

You can also use a similar structure to easily track the activities, monitor workflow, and set appropriate deadlines. Setting restrictions for each unit of work will also aid in avoiding overproduction and optimizing resource allocation.

Production Kanban Board Example

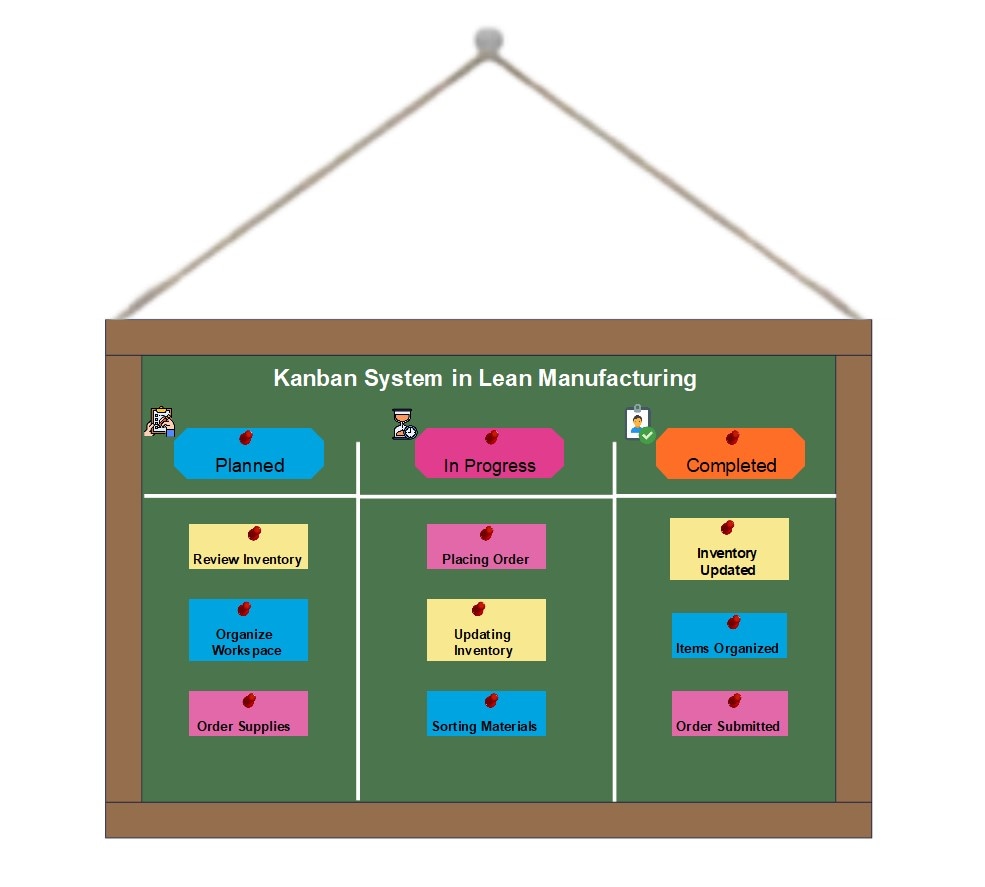

Another example of Kanban lean manufacturing shows how cards are used in a production system to communicate inventory levels and equipment demand. This board begins by reviewing the storage space and moving towards practices to ensure optimal supply. You will see an updated inventory with sorted materials and sufficient equipment supply by the end.

Although short, it covers all the essential activities involved in the manufacturing facility of product-based businesses like Nike and Toyota. By separating the planned, in-progress, and completed tasks, as shown in the example, you can easily track industrial activities and improve production supply with minimal waste.

Manufacturing Operations Kanban Board Example

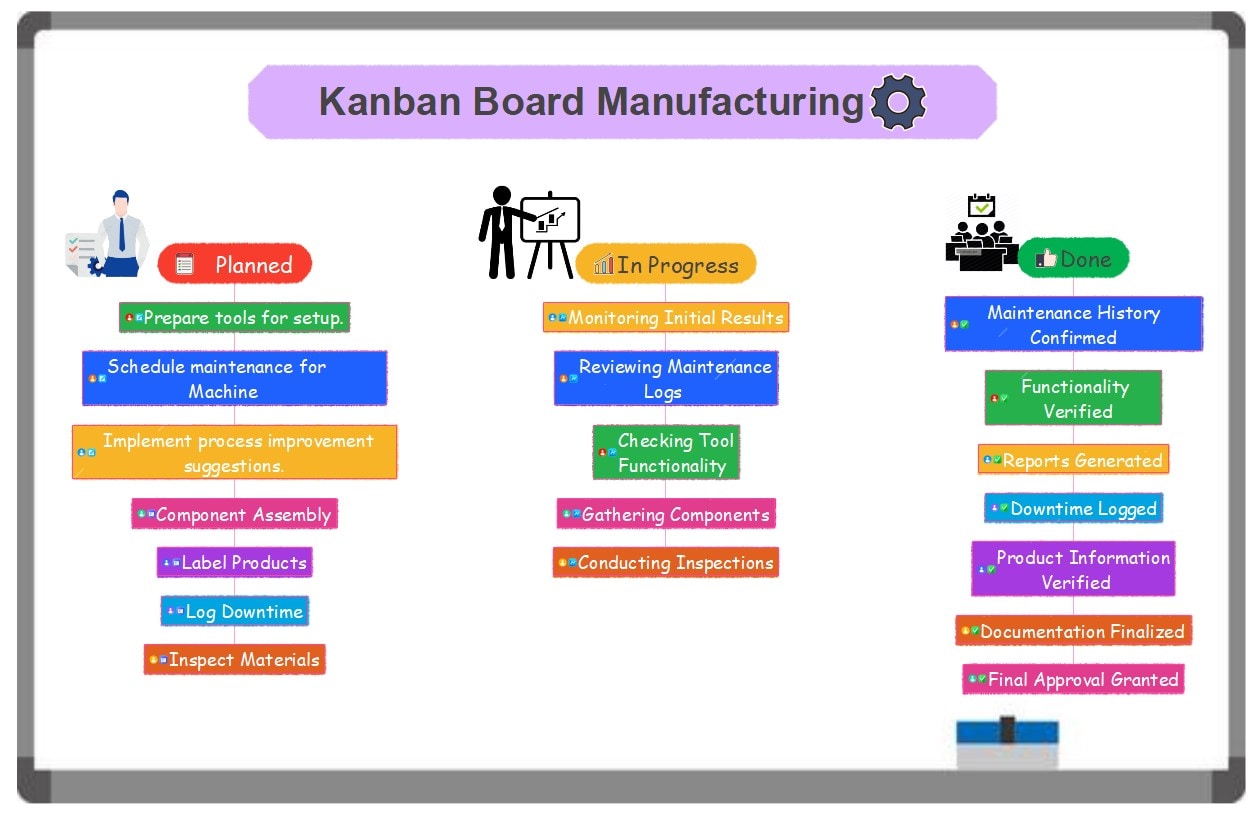

Personalizing a kanban board is an excellent idea, and this example does just that. Companies like Boeing have been known to use this approach.

It uses color-coded cards and graphic details at each manufacturing stage to guide workers about activities that need to be accomplished next. Eventually, in a manufacturing setup, it aids in smooth routine operations and wastes no time.

Such lean manufacturing kanban boards can be applied to an electronics, pharmaceutical, or automotive manufacturing facility.

Automotive Manufacturing Kanban Board Example

Logging and documentation are integral tasks of the automotive manufacturing industry and this Kanban lean manufacturing example emphasizes it. This kanban board highlights the routine preparations, reviews, and verification in a typical assembly facility.

The example also includes other crucial activities, such as functionality checks, inspections, and report generation, making it usable across all scales of industries.

Kanban Board in Manufacturing Example

It is yet another more straightforward take on the Kanban system in manufacturing. This board focuses on essential activities, such as assigning individual tasks and tracking various activities. Such a board works best for basic-level manufacturing systems to remove waste and improve processes.

You can replace the icon with the appropriate employee portrait to keep things organized and streamlined in your manufacturing industry. Color-coding the categories will also help workers better follow the ongoing, completed, and pending tasks.

Benefits of the Kanban Board

Whether you use Kanban in manufacturing or for personal goals, it benefits you on so many levels. Let’s look at them.

- Efficient task management: Kanban boards help you track tasks and their progress more efficiently by distributing them in different groups. It allows for recording individual tasks and evaluating employee performance, all in an organized structure.

- Visual progress tracking: The pen-and-paper approach seems outdated! A Kanban board offers a visual approach rather than textual information, making it easier to grasp.

- Task delegation & collaboration: With all the tasks listed, you can easily assign tasks and allocate resources. It even lets you create organized teams according to the task’s difficulty, promoting team collaboration.

- Improved productivity: Following your routine can sometimes be challenging. Where a simple to-do list fails, a Kanban board shines. It helps you sort your everyday activities or projects in different groups, providing a productive way to meet your deadlines.

- Ideal for lean manufacturing: The entire purpose of lean manufacturing is to minimize waste. This waste doesn’t necessarily mean materials but also time and effort. A Kanban board helps by providing a detailed list of activities. So, you can rule out the unnecessary tasks, saving time and effort.

Best Practices for Using the Kanban Board

Are you ready to boost your productivity with a Kanban board? Here are some tips to achieve desired goals and streamline processes.

Minimize Clutter

The whole point of a Kanban board is to manage tasks efficiently. The first thing should be to eliminate all unnecessary clutter from the board. Or else, it will overwhelm you and the entire team at first sight, distracting focus from the essential tasks.

Distribute Tasks Evenly

Groups are one of the most crucial aspects of a Kanban board. Make sure to assign your tasks evenly in all groups. You can create several task categories like started, planned, in progress, completed, etc.

Use Graphical Elements

The best you can do with a Kanban board is minimize text. Instead, use graphic elements like icons, symbols, color codes, and portraits. It makes the board interactive and more understandable, even for workers.

Manage Workflow

A Kanban board is not just listing tasks but making workflow smoother. The relationship between the tasks in planning, progress, and completion defines the efficiency of a Kanban board. So, as a manager, take your time outlining unit groups and allocating tasks.

How to Create a Kanban Board

Now that we already know the structure of the Kanban board and best practices, why not create one lean manufacturing Kanban board? It may take several minutes if you are using EdrawMind. It lets you create organized, group-wise boards to boost your productivity.

Plus, you can convert these boards into mind maps for visual information representation. Here’s how to do it.

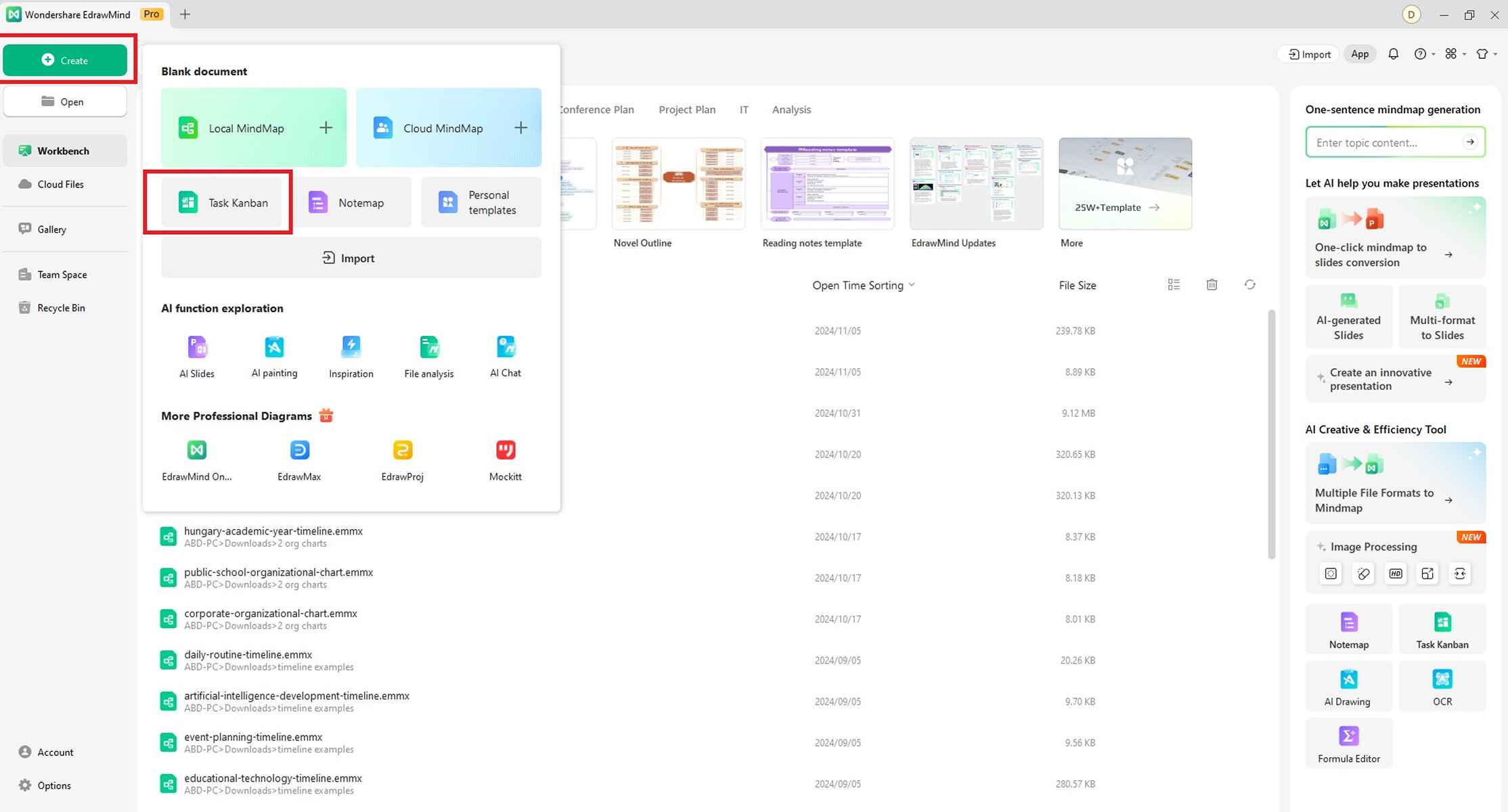

Before you begin, download the EdrawMind desktop version and log into your Wondershare ID.

Step 1:

Click Create > Task Kanban from the top-left corner of the dashboard.

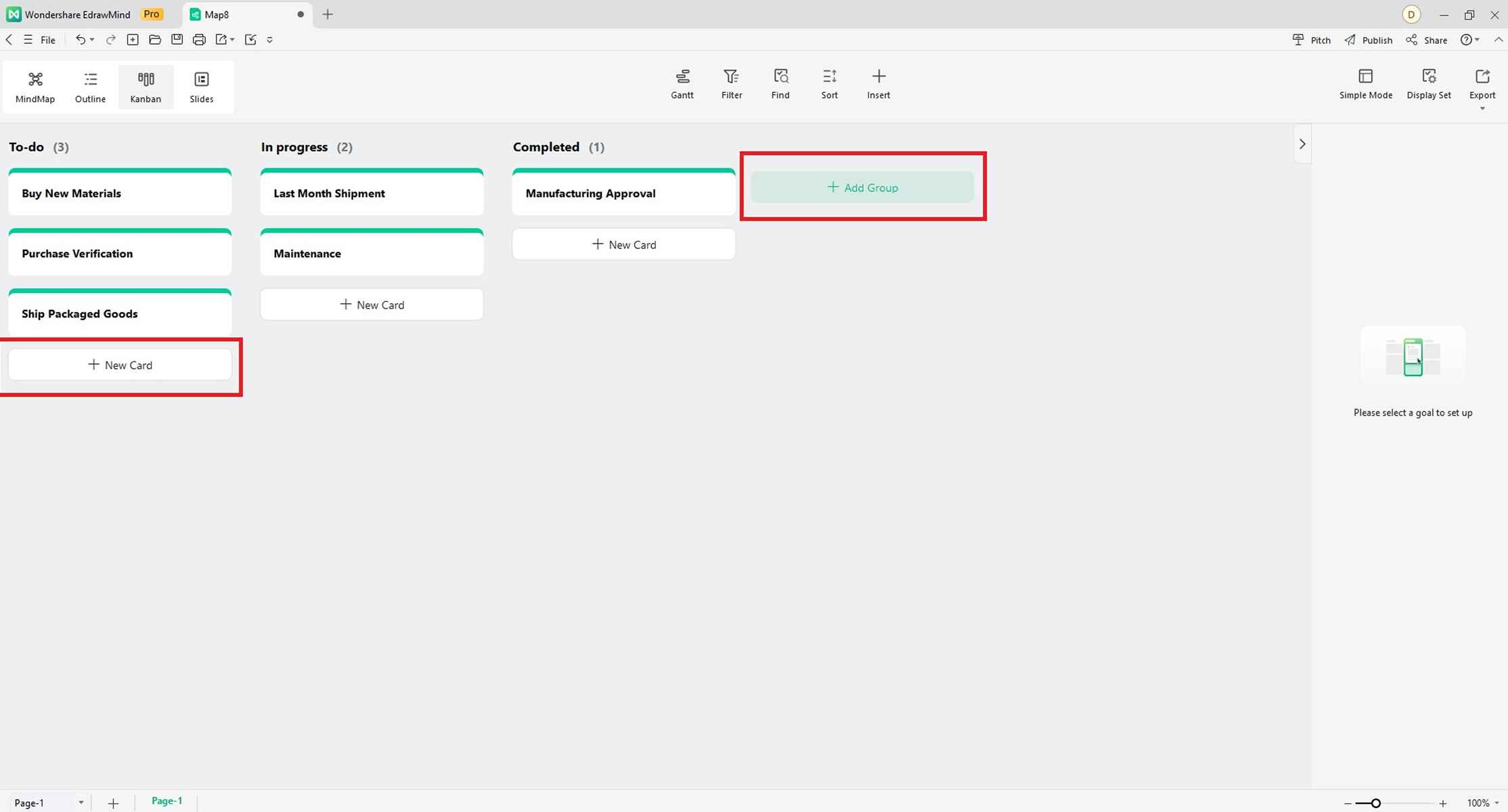

Step 2:

Now, you have a basic Kanban board layout. Create groups and add new cards to customize the board.

Step 3:

Pro-tip: Use the Insert button on the top menu to add images, labels, and attachments to make your Kanban board more visually engaging.

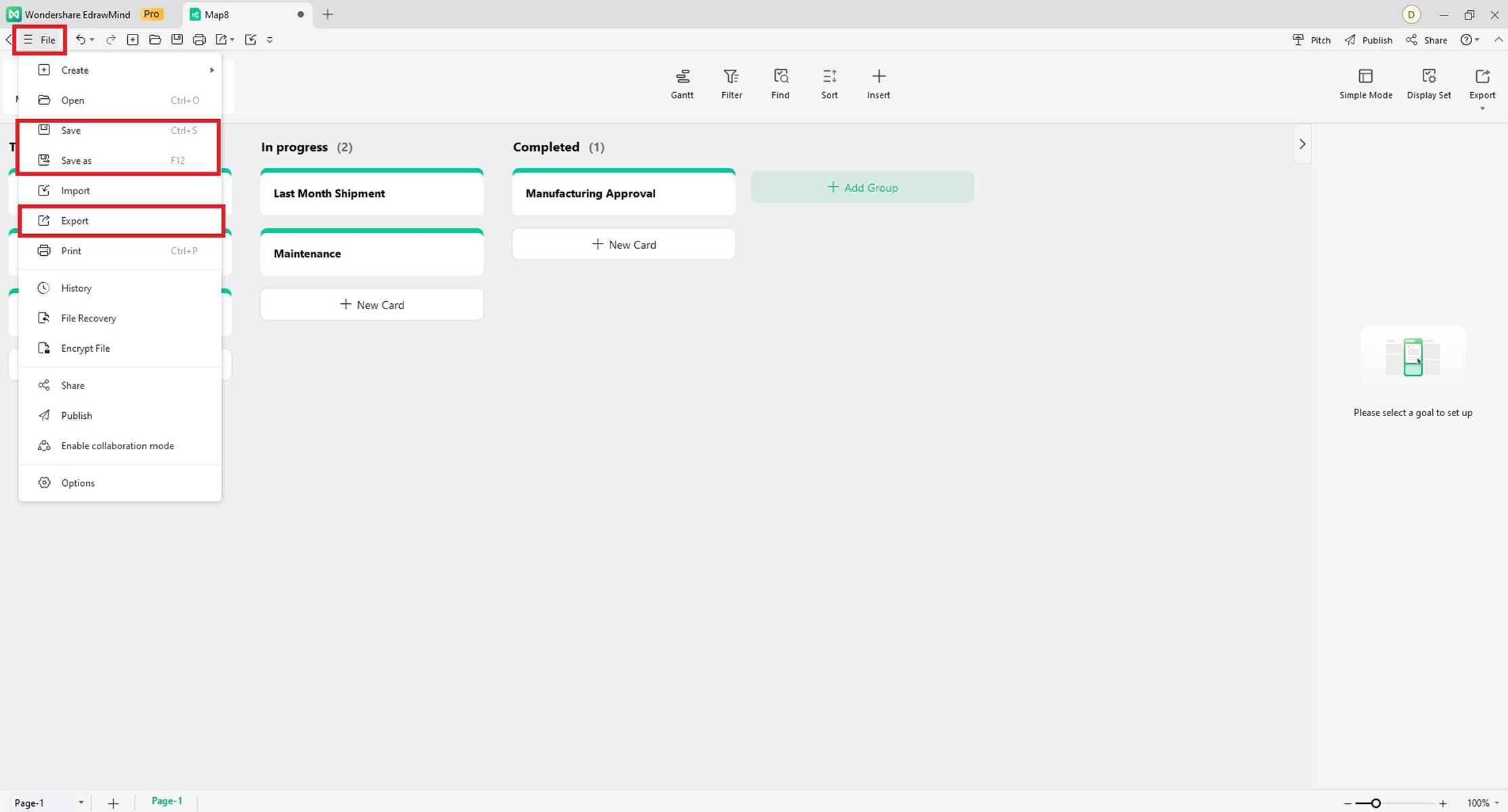

Done making your Kanban board? Click the File button at the top-left corner to Save or Export your project in your required file format.

Ending Note

The scalability of Kanban in manufacturing makes it usable across industries. A Kanban board is the way out if you struggle to minimize waste or maximize your team’s productivity. It is your road map for efficient task management, progress tracking, goal measuring, and more.

A Kanban board does not have to be limited to manufacturing. You can use it for your personal goals, too. Where to begin? Make a Kanban board on EdrawMind, list your daily activities, track them, and analyze your timely performance. Follow it religiously, and you will notice significant improvements!

below.

below.  below.

below.